Our services.

Abstergoes Quality NDT and Inspections, Inc.

Providing Superior CWI Services

At Abstergoes Quality NDT and Inspections, Inc., we take pride in delivering top-notch Certified Welding Inspection (CWI) services to our clients across industries. Our team of highly qualified and experienced welding inspectors ensures the quality and integrity of welds through meticulous inspections and adherence to industry standards.

With a commitment to precision and excellence, we offer CWI services that reinforce safety and reliability of welded structures. Whether it's evaluating welding procedures, conducting visual inspections, or performing destructive and nondestructive tests, we utilize the latest techniques and technology to ensure compliance with regulatory requirements.

Partnering with us means gaining access to a dedicated team that is well-versed in best practices and equipped to identify and address any welding issues promptly. We understand the importance of efficient and accurate welding inspections in maintaining the integrity of structures, and we are here to provide reliable CWI services that exceed expectations.

Contact Abstergoes Quality NDT and Inspections, Inc. today to discover how our CWI services can help elevate the quality and performance of your welding projects. Trust us to be your trusted partner in ensuring the strength and durability of your welded components.

Professional Magnetic Particle Inspection Services

At Abstergoes Quality NDT and Inspections, Inc., we offer top-notch Magnetic Particle Inspection (MPI) services to ensure the integrity and quality of your components. Our MPI technique is a versatile and highly reliable method used to detect surface and near-surface flaws in ferromagnetic materials.

The MPI Process:

Preparation: The component is thoroughly cleaned to remove any contaminants that could affect the inspection process.

Magnetization: The component is magnetized either by direct contact with a magnet or by using an electric current to induce a magnetic field.

Application of Magnetic Particles: Iron particles are applied to the surface of the component. These particles will be attracted to areas where magnetic flux leakage occurs due to surface-breaking defects.

Flaw Detection: A trained inspector will carefully examine the component for indications of cracks, porosity, laps, seams, and other defects using UV light or white light, depending on the type of particles used.

Reporting: A detailed report will be provided, including information on the inspection process and findings.

Why Choose Abstergoes Quality NDT and Inspections, Inc. for MPI?

Experience: Our team of experts has years of experience in conducting MPI inspections across various industries.

Quality Assurance: We adhere to the highest quality standards to ensure accurate and reliable results.

Customer Satisfaction: We prioritize customer satisfaction and aim to exceed your expectations with our services.

Trust Abstergoes Quality NDT and Inspections, Inc. for all your Magnetic Particle Inspection needs. Contact us today to schedule an inspection and experience the difference our professional services can make for your business.

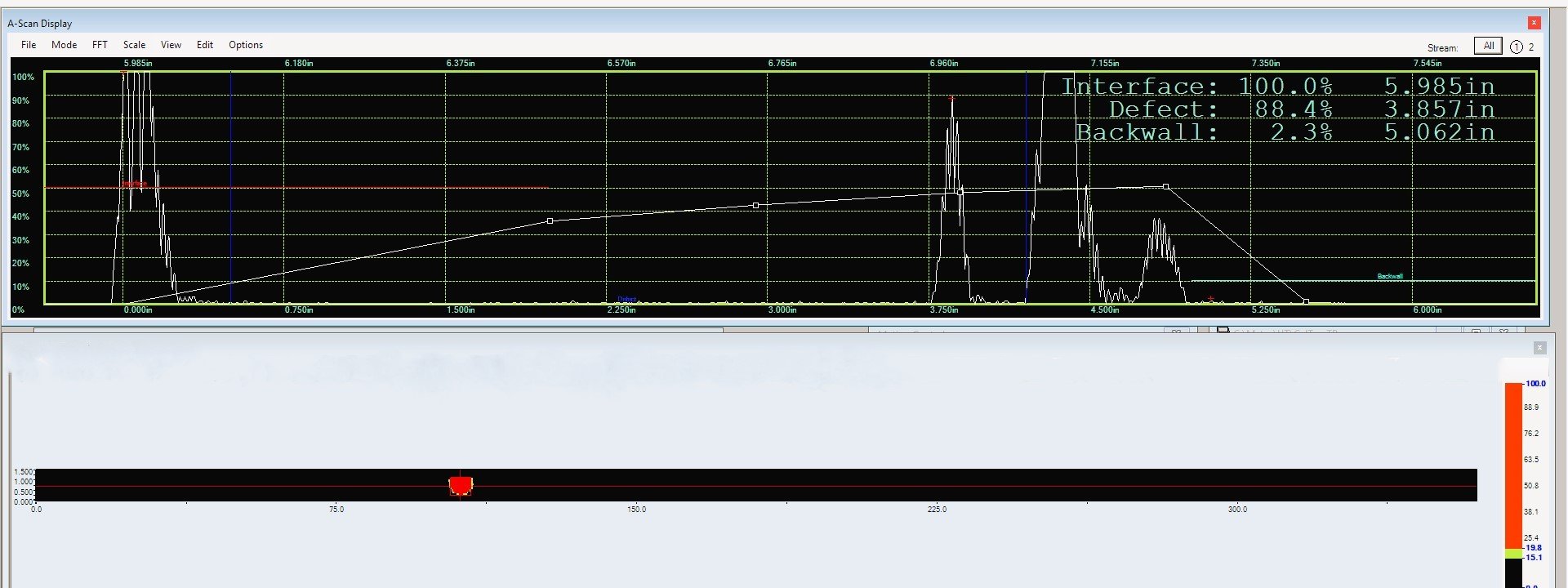

Ultrasonic Testing

Ultrasonic Testing (UT) is a versatile Nondestructive Testing (NDT) technique used to detect surface and subsurface defects in materials. At Abstergoes Quality NDT and Inspections, Inc., our team of certified technicians specialize in performing precise and reliable UT inspections to ensure the integrity of your components and structures.

Key Benefits of Ultrasonic Testing:

Accuracy: UT provides detailed and accurate information about the size, shape, and location of indications.

Versatility: UT can be used on a wide range of materials, including metals, composites, plastics, and ceramics.

Nondestructive: UT is a non-invasive technique that does not damage the test piece, allowing for repeat inspections over time.

Our Ultrasonic Testing Process:

Preparation: Couplant is applied to the part.

Equipment Setup: We use reliable ultrasonic testing equipment to send high-frequency sound waves into the material.

Data Analysis: The reflected sound waves are analyzed to detect and characterize any indications present in the material.

Reporting: Our detailed inspection reports provide clear information on location, depth, and size of indications.

Why Choose Abstergoes Quality NDT and Inspections, Inc. for Ultrasonic Testing?

Experienced Technicians: Our team of technicians are highly trained and certified to perform UT inspections with precision and expertise.

Cutting-Edge Technology: We invest in the latest UT equipment to ensure accurate and reliable results for our clients.

Comprehensive Service: We offer tailored UT solutions to meet the specific needs of various industries, from aerospace to manufacturing.

Trust Abstergoes Quality NDT and Inspections, Inc. for your Ultrasonic Testing needs. Contact us today to learn more about how we can help ensure the quality and safety of your assets.

Phased Array Ultrasonic Inspection Services

At Abstergoes Quality NDT and Inspections, Inc., we take pride in offering cutting-edge Phased Array Ultrasonic Inspection services to meet the needs of our clients in various industries. Our experienced and certified technicians utilize state-of-the-art equipment to provide accurate and reliable inspections for detecting indications and abnormalities in materials.

Benefits of Phased Array Ultrasonic Inspection:

Advanced Technology: Our Phased Array Ultrasonic Inspection technique uses multiple ultrasonic elements to steer, focus, and scan beams, allowing for detailed imaging and precise indication detection.

Efficiency: With the ability to inspect a large area in a single pass, Phased Array Ultrasonic Inspection saves time and reduces downtime for our clients.

Versatility: This method can be applied to a wide range of materials and geometries, making it suitable for various industries such as aerospace, oil and gas, and manufacturing.

Accuracy: Our skilled technicians are trained to obtain the data accurately, ensuring reliable results and helping our clients make informed decisions.

Why Choose Us:

Expertise: Our team consists of knowledgeable professionals with years of experience in Nondestructive Testing, ensuring top-notch quality service.

Innovation: As a young company, we bring fresh perspectives and innovative approaches to address the pain points of industry leaders.

Customer Satisfaction: We prioritize customer satisfaction and strive to exceed expectations by delivering comprehensive inspection reports in a timely manner.

For reliable and efficient Phased Array Ultrasonic Inspection services, trust Abstergoes Quality NDT and Inspections, Inc. to ensure the integrity of your assets. Contact us today to learn more about how we can assist with your inspection needs.

Abstergoes Quality NDT and Inspections, Inc.

Dye Penetrant Testing

At Abstergoes Quality NDT and Inspections, Inc., we understand the critical role that Nondestructive Testing (NDT) plays in ensuring the integrity and safety of industrial components. One of the key methods we utilize is Dye Penetrant Testing.

What is Dye Penetrant Testing?

Dye Penetrant Testing is a widely used NDT technique for detecting surface-breaking defects in a variety of materials, from metals to plastics. This method involves the application of a colored dye to the surface of the material, which is then drawn into any surface indications by capillary action.

Why Choose Dye Penetrant Testing?

Cost-Effective: Dye Penetrant Testing is a cost-effective method for detecting surface defects without causing damage to the test piece.

Versatile: This technique can be applied to a wide range of materials, making it a versatile solution for various industries.

Sensitive: Dye Penetrant Testing can detect very small defects that are not visible to the naked eye, ensuring thorough and accurate inspections.

Our Approach

At Abstergoes Quality NDT and Inspections, Inc., our highly trained technicians follow industry best practices to conduct Dye Penetrant Testing with precision and efficiency. We adhere to strict quality standards to deliver reliable results that our clients can trust.

Contact Us

Trust Abstergoes Quality NDT and Inspections, Inc. for comprehensive Nondestructive Testing services, including Dye Penetrant Testing. Contact us today to learn more about how we can support your quality assurance needs at Abstergoes Quality NDT and Inspections, Inc.